Explore how 3D car wraps are revolutionizing vehicle customization. Learn about textures, designs, materials like TPU, and how CARLAS is driving innovation in automotive personalization.

What Are 3D Car Wraps?

3D car wraps represent a bold leap beyond traditional vinyl films. Unlike flat-surface wraps that rely solely on color or gloss, 3D wraps introduce texture, depth, and visual illusion. They can simulate materials like carbon fiber, brushed aluminum, or even rusted metal—but without the weight or permanence.

These wraps provide not only a visual transformation, but also a tactile one. Whether you’re seeking a futuristic matte hexagon layout or a rugged forged-carbon look, 3D wraps elevate a vehicle from a daily driver to a design statement.

The Technology Behind 3D Wraps

Creating a 3D wrap isn’t just about printing. It’s a layered combination of advanced material engineering, digital design, and heat-activated texture forming.

Embossed and Raised Effects

Some wraps use special techniques like micro-embossing to raise certain patterns on the surface. These films use multi-layer TPU or hybrid materials that hold form when heat is applied during installation.

3D Visual Illusion Wraps

These designs rely on precise use of shadow, contrast, and gradients to make flat wraps appear three-dimensional. Think of it as an automotive version of trompe-l’œil art—where graphics appear to leap off the surface.

Popular 3D Car Wrap Styles

Carbon Fiber & Forged Patterns

These are the most popular styles, offering high-end motorsport looks with textures that mimic real composite materials. They pair especially well with sports cars, performance SUVs, or race builds.

Geometric & Futuristic Prints

Inspired by cyberpunk aesthetics and digital age design, these wraps use clean lines, 3D grids, and angular highlights to give the vehicle a concept-car feel.

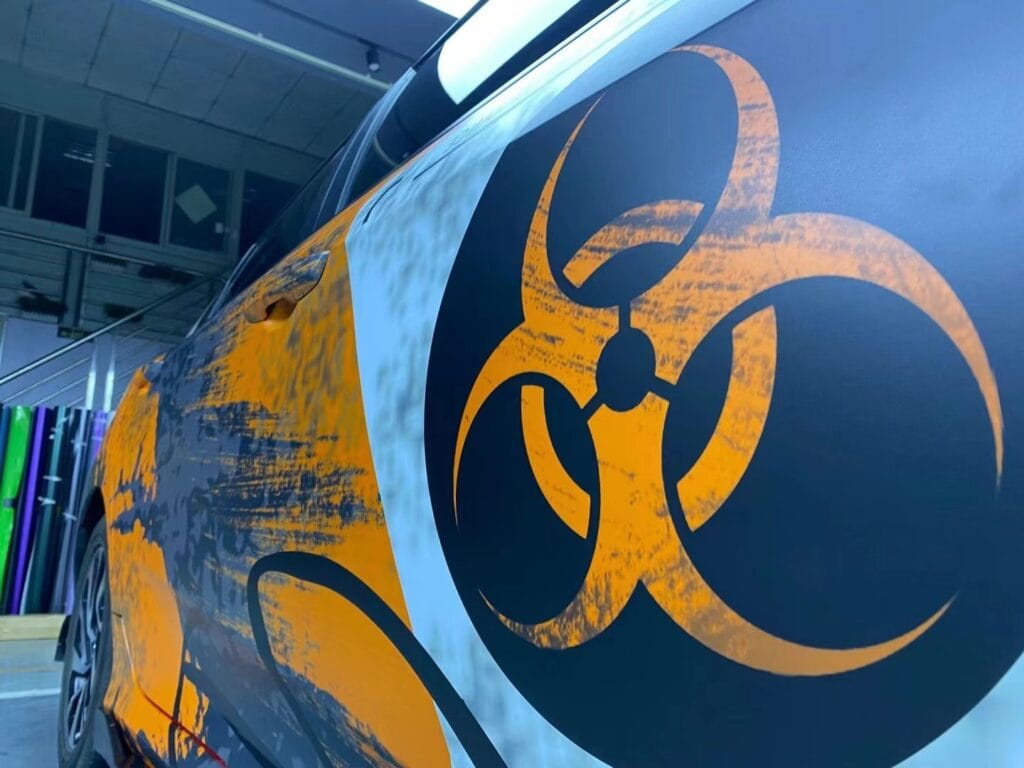

Realistic 3D Illusions (Rust, Metal, Flames)

These wraps mimic aging metal, burning flames, or military armor plating. Perfect for classic car enthusiasts or anyone who wants a heavily themed build.

Materials Used in 3D Wraps

While some 3D wraps still use PVC, higher-end options rely on TPU due to its flexibility and resilience.

Why TPU Is Ideal for 3D Applications

- Greater stretchability without tearing

- Memory properties allow textures to return to form

- Naturally self-healing from minor scratches

- UV and weather-resistant, ideal for long-term outdoor use

Carlas, for example, uses multi-layer TPU wrap film that retains depth and texture even in extreme climates.

Advantages of 3D Car Wraps Over Traditional Methods

- Customization: Design freedom beyond paint

- Reversibility: Can be removed or changed without damage

- Durability: TPU wraps can last up to 10 years

- Paint Protection: Functions as PPF and aesthetic enhancer

- Branding Opportunity: Ideal for business vehicles, especially in advertising fleets

Installation Techniques for 3D Wraps

Due to the complex texture and alignment requirements, 3D wraps require expert handling. Key considerations:

- Surface prep must be flawless (clean, dry, contaminant-free)

- Heat application to stretch and fix embossed patterns

- Use of wrap gloves, air-release tools, and squeegees for bubble-free finish

- Proper seam sealing for long-term durability

Maintenance Tips for 3D Wraps

To preserve appearance and texture:

- Wash every 7–10 days using pH-neutral soap

- Avoid automatic car washes with brushes

- Hand wash with microfiber towels only

- Apply wrap-safe ceramic sprays or hydrophobic coatings every 2–3 months

- Store away from prolonged direct sun when possible

Real-World Use Cases: From Sports Cars to Advertising Fleets

- Enthusiasts use forged carbon or stealth hex-pattern wraps for style

- Car shows demand standout designs—like flames, skulls, or fantasy themes

- Commercial fleets benefit from branded 3D graphics for visual impact

- Motorcycles and boats increasingly adopt textured wraps for both flair and protection

CARLAS Innovation in 3D Wraps

CARLAS is at the forefront of 3D wrap development, combining aesthetic and functional innovation:

- Offers textured TPU series with deep pattern realism

- Develops modular design templates for professional wrappers

- Supports “Training + Product” ecosystems across Asia, Europe, and the Americas

- Focuses on eco-friendly TPU production and smart surface technology

With CARLAS, you don’t just wrap a car—you turn it into a moving masterpiece.

Challenges and Limitations of 3D Wraps

- Cost: Premium materials and labor can be 30–50% more expensive

- Installation difficulty: Requires trained professionals

- Heat resistance: Raised textures may distort under intense or uneven heat if improperly installed

- Repair complexity: Touch-ups are harder than with flat wraps

Future Outlook: What’s Next for 3D Automotive Wraps?

- AI-generated wrap designs tailored to vehicle shape and owner personality

- Augmented reality (AR) previewing for customers to visualize wraps in real-time

- Reactive 3D wraps that change texture or color based on temperature or light

- Integration with vehicle smart sensors for dynamic surface visuals

The market is expected to grow 20–30% annually, especially in luxury, motorsport, and personalization sectors.

FAQs

Q1: How long do 3D wraps last?

Up to 10 years with proper care, especially TPU-based versions.

Q2: Can I wax or polish a 3D wrap?

Use only wrap-safe products. Avoid abrasive compounds or hard waxes.

Q3: Are 3D wraps removable?

Yes, when installed professionally, they can be removed without damaging paint.

Q4: Can I wrap just part of my car in 3D texture?

Absolutely—roof, hood, mirrors, or racing stripes are popular areas.

Q5: What makes CARLAS 3D wraps stand out?

CARLAS focuses on TPU engineering, global quality control, and high-fidelity textures unmatched in the market.

Conclusion: Driving Into the Future with 3D Wraps

3D car wraps aren’t just a trend—they’re a new design language for vehicles. They offer high-end aesthetics, protection, and identity in one customizable package.

Whether you’re a tuner, a business owner, or a luxury car enthusiast, 3D wraps offer a bold, expressive, and futuristic solution. And with leaders like CARLAS pushing the envelope, the road ahead is nothing short of transformational.